Sprint Tool and Die, a British toolmaking company, involved in cutting edge technology to automatically link cavity pressure monitoring with hot runner controller.

Telford based Sprint Tool and Die are working with Kistler Instruments and Polymer Training and Innovation Centre, to install Kistlers latest transducer technology to automatically balance hot runners and eliminate the need for manual optimisation. The Kistler CoMo software communicates with the Mold Masters hot runner controller, so as to achieve constant pressure within each moulding.

Cavity Pressure Monitoring is a well established practice, in terms of putting sensors in a mould tool and using a monitoring system to plot the pressure in each cavity.

But the new technology will not only communicate with the hot runner controller, but it will make necessary adjustments and balances automatically.

Not the first research project that Sprint Tool and Die have become involved with. The Emold project, in which Ian Amos, MD, Sprint Tool and Die, was a research partner, investigated the possible of progressing this information to the next level, so that hot runner systems and controllers could be accessed remotely – from another room, country or continent.

PTIC – Polymer Training and Innovation Centre – www.wolvcoll.ac.uk/polymer

Kistler Instruments Ltd – www.kistler.com

Rapstrap (Dragons Den)

Sprint Tool and Die has recently completed the manufacture of the first two 48 impression tools to produce the Rapstrap, as featured on Dragons Den.

Medical Toolmaking

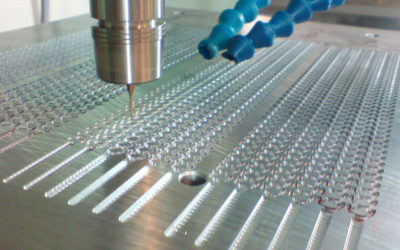

A recent project to produce tools for various cannulae for extensive use within the medical and veterinary industry.